Is this how we'll make things in 2030?

Manufacturing and production will be completely transformed by the Fourth Industrial Revolution Image: REUTERS/Ben Gruber

Subra Suresh

President-Designate and Distinguished University Professor, Nanyang Technological University, Singapore

Get involved with our crowdsourced digital platform to deliver impact at scale

Stay up to date:

Advanced Manufacturing

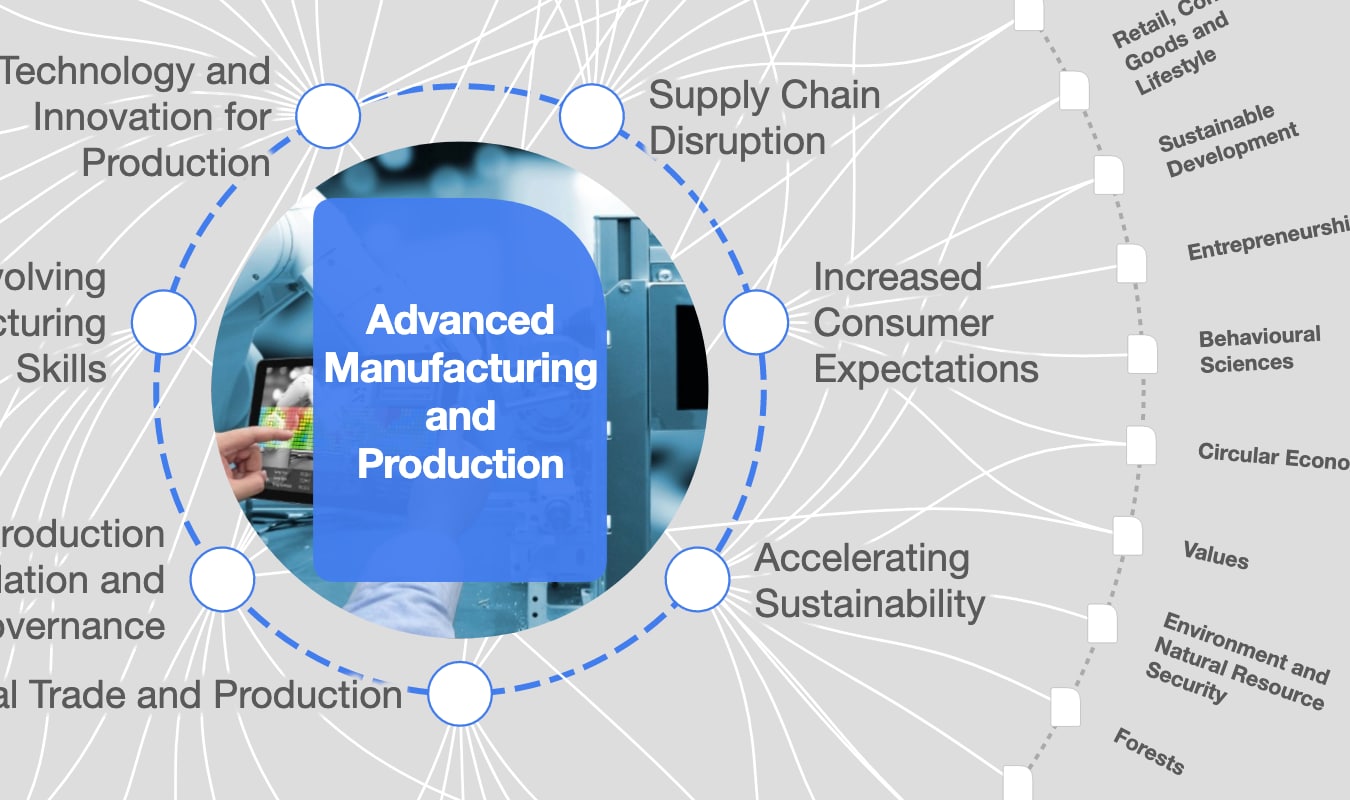

Manufacturing and production systems will be completely transformed by the Fourth Industrial Revolution – a period characterized by a fusion of technologies that is blurring the lines between the physical, digital, and biological spheres.

Dr Subra Suresh, the president of Carnegie Mellon University and co-chair of the Global Future Council on Manufacturing and Production Systems, sees a future where planes fly themselves and prosthetics communicate directly with doctors. In this period of technological revolution, he says policy must keep pace with change to ensure the benefits continue to outweigh any unintended consequences.

First of all, can you explain the critical role of manufacturing and production systems and why it is so important to discuss their future?

In January 2016, the World Economic Forum meeting in Davos had the theme the Fourth Industrial Revolution. The distinguishing feature of the Fourth Industrial Revolution is the unique convergence of the physical and the biological. So, we have areas like artificial intelligence, machine learning, robotics, computing, mobile technology; they are transforming manufacturing.

It’s important that we look at how that impacts employment, how that impacts the disparity between the wealthy, and the middle class, and the lower economic parts of society. Every time we have an intentional use of a technology there are unintended consequences. If we rely exclusively on robots and artificial intelligence, is there a possibility we will cede control to machines? Will we be able to react and correct in a timely fashion so that unintended consequences don’t outweigh the intended benefits?

What are the key themes that arise when we talk about the future of manufacturing and production systems?

The themes would be things such as, what does globalization mean for the future of production? Recent geopolitical trends, from Brexit, to what is happening in the US; the reaction to a fast pace of globalization which is disrupting local economies and creating disparity within individual countries.

Another issue which will come up is when technology has already far outpaced policy – driverless cars are a very good example of this. Who is responsible if there is an accident? That is also going to be an issue in the future of production and manufacturing. How do we respond to the legal issues, the policy issues, the insurance issues?

Can you describe the impact of emerging technologies on production systems?

Emerging technologies will lead to much more customization, for example 3D printing, advanced additive manufacturing. We have the technology today for a student to design her own dress, transmit that to a manufacturer, have it printed on the material she wants, and have it shipped probably within 24 hours.

Then there is data. For an average flight of a Dreamliner, Boeing generates about 1 terabyte of data. The question is, how do you use that information? Can you fix problems in real time? Can you identify a defect in a part, or a problem during the flight and ask the plane to land immediately?

The other area is healthcare, if you have a hip or knee implant, we can make a 3D printed part and we can embed sensors in there, so it can monitor the gait of the patient. If it is not usual for that patient, you can immediately transmit some information to his or her doctor. The downside is, who has access to this data and what will they do with it?

The last point, General Electric has just established an advanced manufacturing prototype facility in Pittsburgh where they can do what they have been doing using conventional techniques in half the time for half the cost. So then the question of pricing and economics comes up. Will this make things cheaper, or will it make it more expensive because there is so much R&D effort involved? Will there be price bulges because someone has a dominance in this area?

How will changes in production systems affect job creation? What can be done to counteract any negative impacts of change?

There is a broad feeling that as automated systems become more and more prevalent, that will have inevitably some negative impact on employment. So the question will be, what is the impact on minimum wages? What is the impact on unionization and negotiating ability for workers? Will policy be driven more by profit, or will it be driven by technology, or will it be driven equally by social welfare?

Different countries may respond to it differently. With increasing globalization, even if countries close their borders, individual citizens of the world can engage in commerce across borders. These are issues that need to come up in the discussion of the Future Council and also public discussion over the next few years.

What is the role of trade and capital flows in future production systems?

Trade policy will have to evolve. If the Alibabas or the Amazons of this world continue to grow the way they have been growing and continue to dominate commerce, how does that affect policy in the future?

The second issue is of multinational corporations producing all around the world but keeping, for tax reasons, most of their profits overseas. The concern in the US among the voting public is that this is one of the reasons why we have a significant deficit, we have a loss of jobs in the US, and the middle class is not doing well. That has to be fixed through taxation policy. What should be the taxation policy in the age of future production?

What will the world’s production systems look like by 2030?

It will be much more customized. If you want to buy a car you could choose the material for the body, you can have your choice of engines, you could customise whether it’s totally driverless or a partially driverless, self-parking car. There will be a whole range of customization even for items that are mass-produced.

Also culturally, the baby boomer generation is very different from Generation X, Generation Y and especially the Millennial Generation, who according to many experts don’t want to own things, whether it’s owning a car or a house, as their parents and grandparents did. Then what does that mean for the future of consumerism, which will invariably affect production?

The other interesting trend about future of production, if robots and driverless cars and, in the future, driverless aircraft, trains and other systems, come into existence will that be better for senior citizens, or is it worse? If children don’t take care of their parents, will robots assist senior living?

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

The Agenda Weekly

A weekly update of the most important issues driving the global agenda

You can unsubscribe at any time using the link in our emails. For more details, review our privacy policy.

More on Manufacturing and Value ChainsSee all

Andre S. Yoon and Kyoung Yeon Kim

April 23, 2024

Andrea Willige

March 19, 2024

Raimund Klein

March 4, 2024